When producing large-size sliding doors, dividers and partitioning, tables and bench tops, the risk of warping or bowing is very high.

When producing large-size sliding doors, dividers and partitioning, tables and bench tops, the risk of warping or bowing is very high.

The so-far unequalled solid wood solution, is triple-core poplar blockboard.

Triple-core blockboard is a special construction with 3-ply of cross-banded blockboard cores, overlaid by poplar veneer or thin HDF.… Read more...

Laminated blockboard, a durable decorative lumber core

One of the latest industrial applications on blockboard, consists in overlaying the panel with a durable decorative surface material, called continuous high pressure laminate (cHPL or CPL). This panel has special performance properties including chemical, fire, and wear resistance, which add to the well-known great features of blockboard.

Some of the most common enforcements are structures for upper and lower kitchen cabinets, workbenches, child room and office furniture, and all kinds of articles that require excellent resistance to scratch and hard use.… Read more...

HDF with plywood or blockboard sandwich panels

Production of high quality door profiles and door components can be obtained with a sandwich panel, combining 2 or 3 plies of high density fiberboard (HDF) and plywood or blockboard as the core material.

Production of high quality door profiles and door components can be obtained with a sandwich panel, combining 2 or 3 plies of high density fiberboard (HDF) and plywood or blockboard as the core material.

This kind of board can guarantee high stability and moisture resistance, high bending strength and light weight.… Read more...

Blockboard for door jambs, door frames, and architraves

Blockboard – unlike MDF – is a high-quality product with a long-lasting quality effect, guaranteeing long-term stability and non-deformability.

Blockboard – unlike MDF – is a high-quality product with a long-lasting quality effect, guaranteeing long-term stability and non-deformability.

Door jambs, door frames, and architraves are some of the most common applications for double-core blockboard.

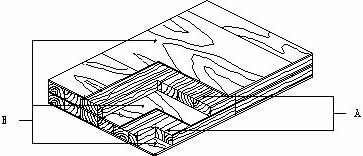

The normal double-core composition is a 5-ply construction:

– about 2 mm veneer cross grain (poplar or fromager) (B)

– about 16,5 mm blockboard core long grain (spruce, pine or poplar) (A)

– about 3 mm veneer cross grain (poplar or fromager) (B)

– about 16,5 mm blockboard core long grain (spruce, pine or poplar) (A)

– about 2 mm veneer cross grain (poplar or fromager) (B)

This kind of board is ideal for producing veneered door jambs.… Read more...