Lightweight particle board poplar panels are unique both in their appearance and in their physical and mechanical properties. They have a compact core of environmentally-friendly poplar timber, and a fine surface with micro-particles with very light color, typical of the wood they are 100% made of.

Lightweight particle board poplar panels are unique both in their appearance and in their physical and mechanical properties. They have a compact core of environmentally-friendly poplar timber, and a fine surface with micro-particles with very light color, typical of the wood they are 100% made of.

The careful selection of poplar timber particles, mostly coming from trees discarded by sawmills and plywood producers, ensures excellent stability and high workability even at the edges, as well as ease of cutting, machining, milling, and molding processes.… Read more...

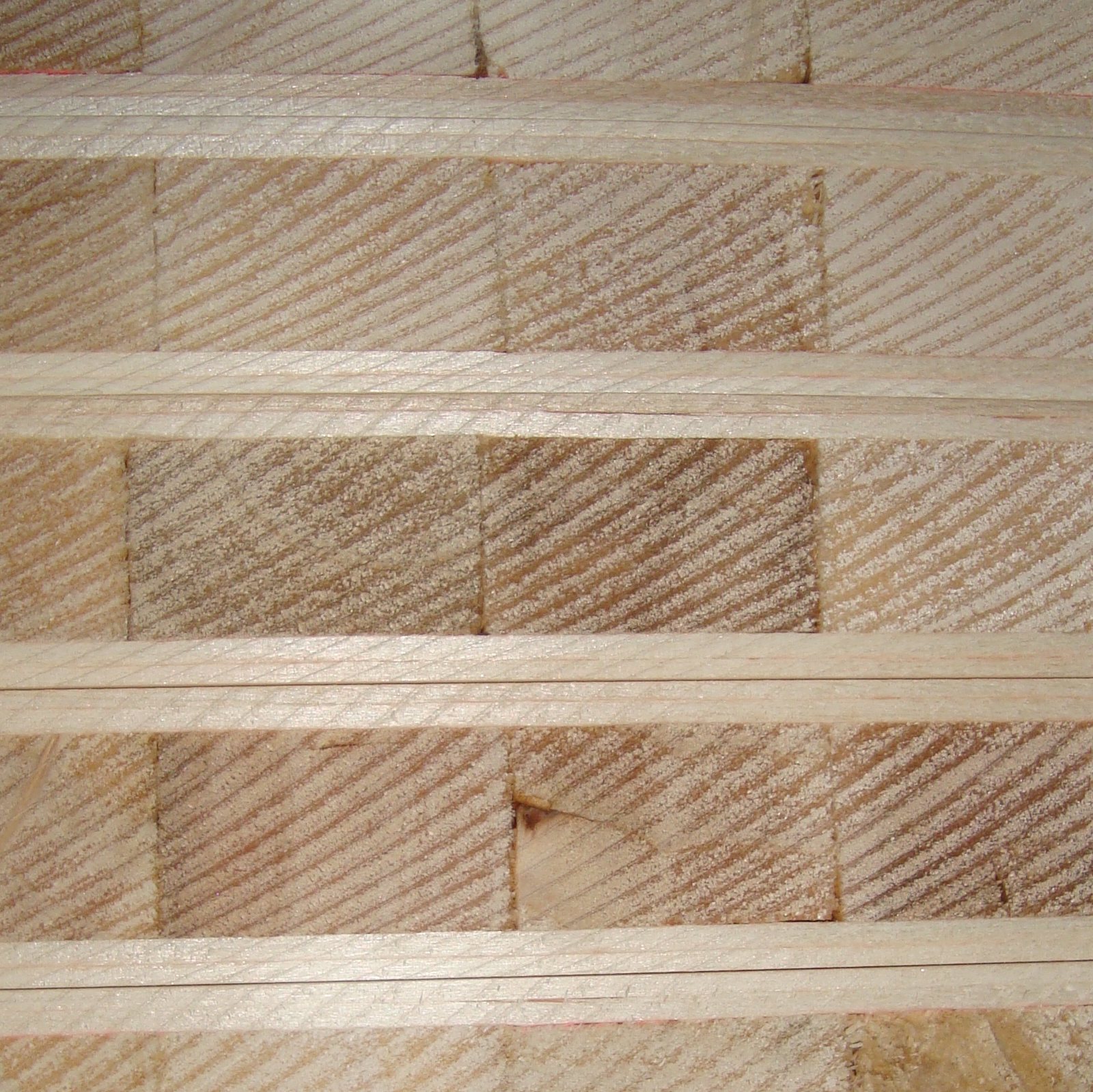

Blockboard (aka lumber core) is well known worldwide due to its characteristics of bending strength, lightness and screw-hold ability. As it’s a real solid-wood alternative to timber, suitable for the production of high-quality and long-lasting furniture and furnishings. It is commonly used for shutters (also with large dimensions), structural components (shoulders), long book shelves, partition walls and cabinet-making.…

Blockboard (aka lumber core) is well known worldwide due to its characteristics of bending strength, lightness and screw-hold ability. As it’s a real solid-wood alternative to timber, suitable for the production of high-quality and long-lasting furniture and furnishings. It is commonly used for shutters (also with large dimensions), structural components (shoulders), long book shelves, partition walls and cabinet-making.…