Germany announced DIN EN 16516 as the new reference method for formaldehyde emission for wood-based materials. This standard will become effective on January 1st, 2020.

If there will be no last-minute extensions, from January 1st, 2020 several things will change for those who produce wood-based panels and have customers (direct or indirect) in Germany. The legislation is still not very clear, but I tried to outline the current facts, starting from the general situation and the moving to the European / German one.

Urea-formaldehyde (UF) is a non-transparent thermosetting resin. It is produced from urea and formaldehyde. These resins are used in adhesives, finishes, and most kinds of panel products, like particleboard, medium-density fiberboard (MDF), plywood, etc.

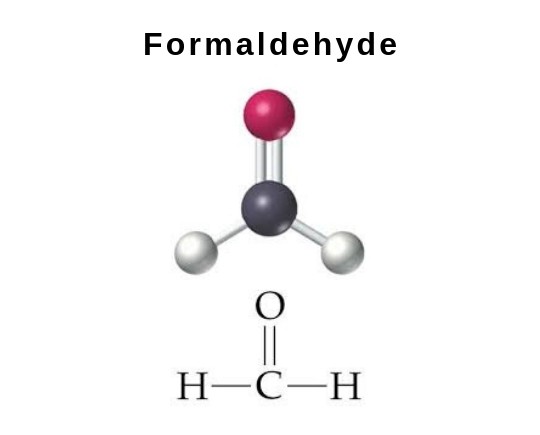

Formaldehyde (the commonly used name of this substance comes from its similarity and relation to formic acid) is a naturally occurring organic compound of carbon, hydrogen and oxygen expressed with the chemical formula CH2O. Formaldehyde is an important precursor to many other materials and chemical compounds. Because of its widespread use, toxicity, and volatility, formaldehyde constitutes a significant danger to human health: it is a colorless gas with a sharp smell only in concentrated form.

In 2011, the US National Toxicology Program described formaldehyde as “known to be a human carcinogen“. It may cause allergy, has a negative impact on genetic material, reproductive organs, the respiratory tracts, the eyes and the skin.

On June 1st, 2018 EPA – the Environment Protection Agency – has anticipated the entry into force in the USA of the regulation concerning formaldehyde emission from composite wood products. Its title is “Formaldehyde Emission Standards for Composite Wood Products Rule” and it adopts the limits of formaldehyde emissions already set by CARB (California Air Resources Board). Starting from the 1st June 2018 all wood-based panels and products containing panels (such as furniture), must comply with formaldehyde emission limits in order to be allowed into the US market .

EPA has adopted the California law enacted by CARB which imposes compliance with formaldehyde emission limits to producers, importers, distributors and panel transformers: 0.05 parts per million (ppm) for plywood; 0.09 ppm for particleboard; 0.11 ppm for fiber panels (MDF) and 0.13 ppm for thin MDF panels (with a thickness of up to 8 mm).

Manufacturers of wood-based panels who want to export their products to the US have to produce panels that comply with the emission limits set by CARB ATCM Phase II or U.S. EPA TSCA Title VI (both prescribe the same limits) and to certify them through a TPC (Third Party Certifier) recognized by CARB and EPA. The panels or their packaging must then be labeled as conforming to the TSCA Title VI (Toxic Substances Control Act), reporting the manufacturer’s name, the lot number, the TPC number recognized by the EPA and the declaration that the product conforms to the Title VI of the TSCA.

At the moment according to EN 717-1, E1 is a standard of safety recognized in Europe. This standard signals the maximum levels of formaldehyde of each wood-based panel. E1 standard says that acceptable formaldehyde emissions are an emission level of 0.10 ppm, that is still the limit recommend by World Health Organization.

In Europe, there are harsh debates in order to reduce the E1 emission limits, however the European Union has not yet taken a harmonized directive. In the meantime, Germany has unilaterally chosen its own path and a revision for the analysis of formaldehyde emissions from wood-based products is coming into force starting from January 1st, 2020.

In November 2018, the German Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (Bundesministerium für Umwelt, Naturschutz und nukleare Sicherheit, BMU) announced DIN EN 16516 as the new reference method for formaldehyde emission (in a chamber) from coated and uncoated wood-based materials under the Chemicals Prohibition Ordinance (ChemVerbV).

The announcement, published in the Federal Register (Bundesanzeiger, BAnz AT 26.11.2018 B2), allows the existing EN 717-1 method to be used in parallel with the new method, but requiring the concentration value of formaldehyde in EN 717-1 to be multiplied by a factor of two (2). It also allows EN ISO 12460 Parts 3 and 5 standards only to be used for correlations in production control under certain prerequisites.

The new analytical processes essentially result in a 50% decrease in the current formaldehyde emission limit value. Therefore, with reference to the E1 emission class according to EN 717-1, in the sector of plywood, blockboard, particleboard, MDF, they now talk about the E05 class (limit value = 0.05 ppm). All products (panels or even furniture, doors, etc.) produced by 31 December 2019, can still be used and sold in Germany without limitation, even after the law comes into force, until exhaustion, because the products that respect the law current E1 standards are not harmful to health. But starting from 1 January 2020, both the raw panels (uncoated), and those covered with a suitable coating that are used in Germany, must comply with the E05 standard according to EN 717-1.

The phrase “suitable coating” defines a product with multiple layers, such as for example laminated doors, which can still contain inside them material with reference to the E1 standard according to EN 717-1. In assessment of emissions, the coating is considered as a method to reduce emissions.

My personal comment is that this norm goes in the right direction for the demand to reduce formaldehyde emissions, but it would have been more correct to have a harmonized regulation in all EU countries. Moreover, the admitted use of E1 panels in products with a”suitable coating” leaves many possible interpretations that I hope will be clarified in the coming months.

Any comments on this or integration/correction to my article will be very welcome.

More interesting information on this page (in German) https://www.dds-online.de/branche/ein-beherztes-ja-zu-e05/

Hi Walter,

Thanks for a great walkthrough. If a product is EN 16516 certified does it have to be CARB certified as well to be exported to the USA or is it de facto CARB compliant?

Best regards,

Lars