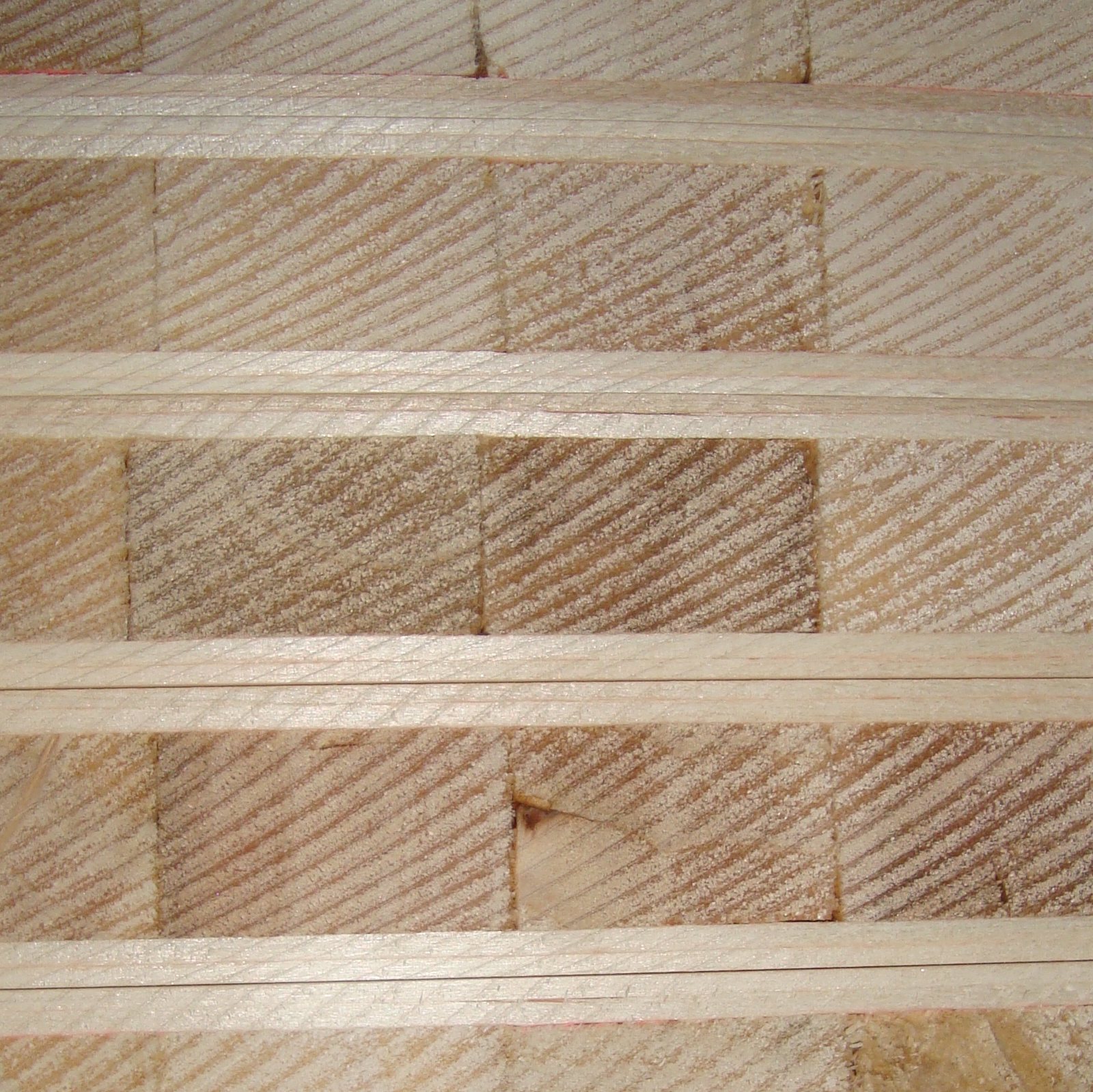

Block-board (also called lumber core) is a timber material consisting of a core of wooden strips placed between two layers of veneers (3-ply in all), with extraordinary characteristics of bending strength, lightness and screw-hold ability. As it’s a real solid-wood alternative to timber, suitable for the production of high-quality and long-lasting furniture, furnishings, partition walls and cabinet-making.… Read more...

Block-board (also called lumber core) is a timber material consisting of a core of wooden strips placed between two layers of veneers (3-ply in all), with extraordinary characteristics of bending strength, lightness and screw-hold ability. As it’s a real solid-wood alternative to timber, suitable for the production of high-quality and long-lasting furniture, furnishings, partition walls and cabinet-making.… Read more...

5-layer blockboard, the light and stable lumber core

Blockboard (aka lumber core) is well known worldwide due to its characteristics of bending strength, lightness and screw-hold ability. As it’s a real solid-wood alternative to timber, suitable for the production of high-quality and long-lasting furniture and furnishings. It is commonly used for shutters (also with large dimensions), structural components (shoulders), long book shelves, partition walls and cabinet-making.… Read more...

Blockboard (aka lumber core) is well known worldwide due to its characteristics of bending strength, lightness and screw-hold ability. As it’s a real solid-wood alternative to timber, suitable for the production of high-quality and long-lasting furniture and furnishings. It is commonly used for shutters (also with large dimensions), structural components (shoulders), long book shelves, partition walls and cabinet-making.… Read more...

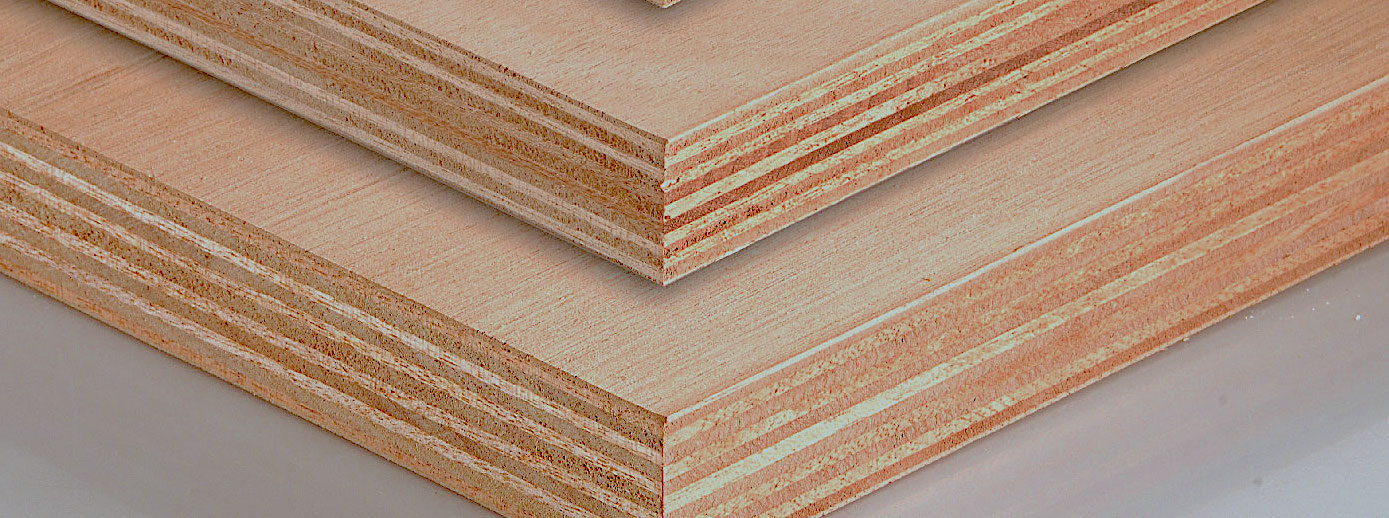

Okoume marine plywood

Okoumé plywood panels are produced with high-quality rotary-cut veneers of Aucoumea klaineana, specially manufactured to provide durability and longevity. They are very stable and can withstand exposure to severe weather conditions for prolonged periods of time.

“Marine” plywood panels are veneered-based panels of good durability with respect to fungal decay and bonding quality, which makes them suitable for the manufacturing and interior fittings of marine craft and for several applications in building construction.… Read more...

HDF with plywood or blockboard sandwich panels

Production of high quality door profiles and door components can be obtained with a sandwich panel, combining 2 or 3 plies of high density fiberboard (HDF) and plywood or blockboard as the core material.

Production of high quality door profiles and door components can be obtained with a sandwich panel, combining 2 or 3 plies of high density fiberboard (HDF) and plywood or blockboard as the core material.

This kind of board can guarantee high stability and moisture resistance, high bending strength and light weight.… Read more...

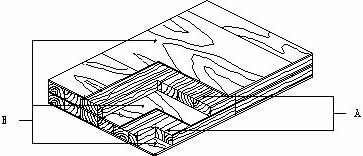

Blockboard for door jambs, door frames, and architraves

Blockboard – unlike MDF – is a high-quality product with a long-lasting quality effect, guaranteeing long-term stability and non-deformability.

Blockboard – unlike MDF – is a high-quality product with a long-lasting quality effect, guaranteeing long-term stability and non-deformability.

Door jambs, door frames, and architraves are some of the most common applications for double-core blockboard.

The normal double-core composition is a 5-ply construction:

– about 2 mm veneer cross grain (poplar or fromager) (B)

– about 16,5 mm blockboard core long grain (spruce, pine or poplar) (A)

– about 3 mm veneer cross grain (poplar or fromager) (B)

– about 16,5 mm blockboard core long grain (spruce, pine or poplar) (A)

– about 2 mm veneer cross grain (poplar or fromager) (B)

This kind of board is ideal for producing veneered door jambs.… Read more...