Block-board (also called lumber core) is a timber material consisting of a core of wooden strips placed between two layers of veneers (3-ply in all), with extraordinary characteristics of bending strength, lightness and screw-hold ability. As it’s a real solid-wood alternative to timber, suitable for the production of high-quality and long-lasting furniture, furnishings, partition walls and cabinet-making.

Block-board (also called lumber core) is a timber material consisting of a core of wooden strips placed between two layers of veneers (3-ply in all), with extraordinary characteristics of bending strength, lightness and screw-hold ability. As it’s a real solid-wood alternative to timber, suitable for the production of high-quality and long-lasting furniture, furnishings, partition walls and cabinet-making.

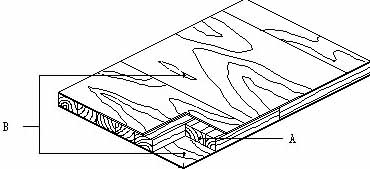

Composition

A. The center of the panel (block-board core) is a solid slab generally made with side-glued lumber strips in the width of 28-38 mm; the most common kiln-dried soft wood timber species used in the cores are poplar, spruce and pine.

B. The block board core (long-grain) is then glued under high pressure with one layer of crossband veneer sheet on each side. The veneer used is normally poplar or Ceiba pentandra (exotic veneer from timber plantation wood, also called fromager or fuma), with a minimum thickness of about 2 mm per side.

While most block-board manufacturers are producing the 3-ply construction, in Italy the special 5-ply blockboard has been developed.

Standard sizes

1300×3050 mm

1880×3140 mm (*)

1880×3680 mm

2070×2800 mm

2070×4200 mm

(*) = most common size

Thickness

13 to 30 mm

(other thicknesses are available with double-core construction)

Special sizes and thicknesses upon request.

| Technical specifications | ||

| Thickness tolerance | +/- 0,3 mm | |

| Length tolerance | +/- 5 mm | |

| Width tolerance | +/- 5 mm | |

| Tolerance in squaring | 2 mm/m | |

| Moisture content (at delivery) | 8-12% | |

| Reaction to fire (EN 13501-1) | D-s2,d0 – Dfl-s1 | |

| Density (EN 323) for poplar core | about 420 kg/m3 | |

| Density (EN 323) for spruce core | about 450 kg/m3 |

Bonding of the faces is made with urea-formaldehyde glue (UF) (formerly called IF20), while the lumber core is bonded with PVAc (D3), in compliance with the provisions of the EN 314 standard.

After suitable treatment in view of resistance to humidity, the board complies to Class 1 requirements for the use of boards in dry environments (EN 636-1).

Class 2 (formerly called AW100 or MR) can also be produced upon request.

Formaldehyde emissions are below those established for Class E1 in conformity with the EN 636 standard. The low-emission class E1 panels do not cause a concentration of equilibrium in the air of the test chamber (defined in the EN 717-1 standard) greater than 0.1 ppm, the limit established by the World Health Organization for living and residential environments.

If you are looking for a reliable supplier of this product or you need more technical information, please contact me using the form on this page.

If you want to improve the information I provided on this page, or you simply want to add your comments or experience about this product, feel free to post a comment below.

Hi we are interested in blockboard core. That is blockboard with just the lumber and without core and face veneers. Can you supply ?

Thickness 13mm and 21mm.

Size 4×8

Please advise